What Is a Smart Warehouse and How Does It Work?

In today’s fast-paced world, technology plays a crucial role in optimizing various industries, including warehousing and logistics. One of the latest innovations in this field is the concept of a smart warehouse. But what exactly is a smart warehouse, and how does it work? Let’s dive into the details.

What is a Smart Warehouse?

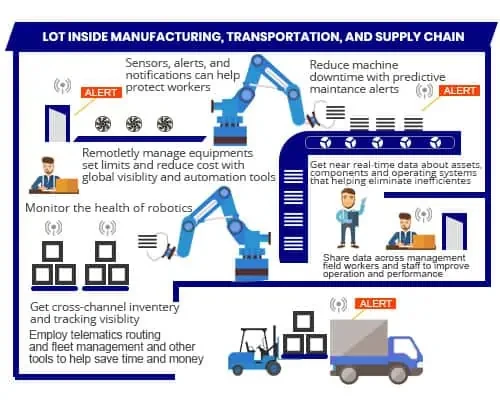

A smart warehouse is a technologically advanced facility that uses automation and cutting-edge technology to improve efficiency, accuracy, and productivity in the warehousing process. By integrating IoT (Internet of Things), AI (Artificial Intelligence), robotics, and other emerging technologies, smart warehouses can streamline operations and provide real-time insights for better decision-making.

Key Components of a Smart Warehouse

IoT sensors: These sensors are strategically placed throughout the warehouse to collect data on inventory levels, temperature, humidity, and other key indicators.

AI-driven software: AI algorithms analyze the data collected by IoT sensors to optimize processes, predict demand, and reduce errors.

Robotics: Automated guided vehicles (AGVs) and robotic arms are used for tasks such as picking, packing, and sorting, reducing the need for manual labor.

Warehouse Management System (WMS): WMS software coordinates all warehouse activities, from inventory tracking to order fulfillment, ensuring smooth operations.

How Does a Smart Warehouse Work?

Smart warehouses operate by seamlessly connecting various technologies to create a highly efficient and intelligent ecosystem. Here’s a step-by-step breakdown of how a smart warehouse works:

Inventory management: IoT sensors continuously monitor inventory levels and provide real-time updates to the WMS.

Order processing: AI algorithms analyze historical data and current trends to predict demand and optimize picking routes for efficient order fulfillment.

Picking and packing: Robots and AGVs pick items from designated locations and deliver them to the packing area, where they are sorted, packed, and prepared for shipping.

Shipping and logistics: Automated systems coordinate with transportation providers to schedule deliveries and track shipments in real-time.

Benefits of a Smart Warehouse

The adoption of smart warehouse technologies offers a wide range of benefits for businesses, including:

Increased efficiency: Automation reduces manual labor and improves operational speed and accuracy.

Cost savings: Lower labor costs, reduced errors, and optimized processes lead to significant cost savings.

Better inventory management: Real-time data insights help businesses track inventory levels, prevent stockouts, and reduce excess inventory.

Enhanced customer satisfaction: Faster order processing and accurate shipments result in improved customer experience and loyalty.

Conclusion

In conclusion, a smart warehouse is a game-changer for the warehousing and logistics industry, offering unparalleled efficiency, accuracy, and productivity. By leveraging advanced technologies such as IoT, AI, and robotics, smart warehouses enable businesses to stay competitive in today’s fast-paced market. As technology continues to evolve, smart warehouses will become the norm, revolutionizing the way goods are stored, picked, and shipped.